VERSATILE TIG AC / DC PULSE

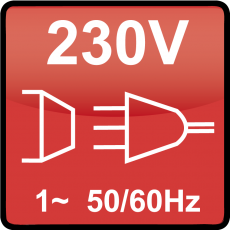

SPARTUS® EasyTIG 200P AC/DC is digitally controlled inverter welding machine, constructed on the basis of IGBTs and PWM technology. Allows welding AC/DC TIG and AC/DC MMA. It is powered with single-phase 230V source power.

Machine enables two methods of arc ignition: TIG HF and TIG Lift. In addition, it has a built-in pulse welding function, which is useful to join very thin elements.

The easy-to-use function panel allows precise control of all the most important welding parameters. The modern display, using the TIG function waveform, facilitates the management of advanced parameters:

-pre-gas and post–gas,

– start amps, peak current and end amps,

– up slope and down slope,

– AC frequency (with mileage control),

– AC balans (20 – 80%),

– SPOT welding

and during welding with pulsed current:

– pulse width ( 5-100%),

– base current (10-200A),

– pulse frequency (0.5 – 200Hz).

Depending on the welder’s preferences EasyTIG 200P AC/DC can work in 2T or 4T mode.

MMA welding mode (to 200A) is assisted by functions: Arc Force and Hot Start.

The machine has 6 channels on which you can set and save your own welding parameters in the device memory.

SPARTUS® EasyTIG 200P AC/DC is designed and manufactured in order to fieldwork. Despite its small dimensions and weight, it allows for advanced welding TIG method.

Examples of use: portable repair, workshop, maintenance, light constructions.

CONTROL OPTIONS:

Standard foot pedal

Potenciometer in the torch