SYNERGIC MIG / MAG WELDING

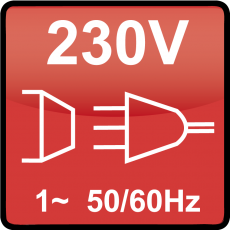

SPARTUS® EasyMIG 210S is a modern, inverter welding semi-automatic device, based on IGBT transistors. It enables welding by means of a consumable electrode shielded by inert (MIG) or active (MAG) gases, welding with coated electrode (MMA) and TIG lift welding. In addition, the device thanks to the ability to change the polarity of welding, enables welding with flux cored welding wire without gas. The maximum welding current for the MIG / MAG / TIG method is 200A. For the MMA welding method it is 160A. The unit is powered from single-phase network 230V.

SPARTUS® EasyMIG210S is equipped with synergistic programs for MIG / MAG welding with steel wires in the range diameter 0,6 / 0,8 / 1,0 mm. In addition, the device has an ability to manually adjust set parameters. Easy change of polarity allows a gas-free self-shielding wire welding.

Thanks to the use of modern technological solutions, the welder is equipped with a number of functions supporting the welding process:

– 2T / 4T – possibility to choose one of two operating modes (MIG/ MAG)

– welding inductivity regulation — face fusion width and deep control (MIG/MAG), reduction of welding splinters

– Hot Start – an easier electrode ignition (MMA)

– Arc Force – an easier welding in forced positions (MMA)

– VRD – reduced no-load voltage (MMA)

Professional two-roller feeder allows smooth and uniform feed of the welding wire. Stable output parameters ensure obtaining high-quality weld. Examples of use: workshop, portable repair, automotive, exhaust silencer welding.