INNOVATIVE, PORTABLE, MULTI-PROCESS, SYNERGISTIC MIG.

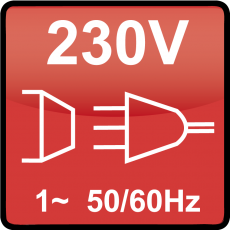

SPARTUS MasterMIG 200PFC is a professional, portable, multi-process welding semi-automatic device. It enables MIG/MAG, TIG and MMA welding with maximum welding current of 200A. The unit is powered from a single-phase network 230V.

The device was produced with using of modern solutions such as inverter technology, IGBT power transistors, MCU controller, PWM technology, PFC filter. All of our technology solutions provide stable output performance under a variety of conditions, which has a direct effect on outstanding arc characteristics and welded joint quality.

The device has a number of functions that support MIG / MAG welding processes:

– Synergistic MIG/MAG welding mode: 16 dedicated programmes.

– Wave Control – precise arc dynamics adjustment Wave control ensures full control over the welding arc: it allows to reduce the amount of welding splashes and controls the width and depth of fusion.

– Burn Back – precise adjustment of welding wire burning speed allows limit a risk of sticking the welding wire to the contact tip.

– Slow Feed – so called gentle start-up of the wire feeder, recommended especially during welding with high amperage and high speed s of wire feed. Smooth start of wire feed eliminates the risk of welding defects at the beginning of the weld.

– 2T / 4T – Choice of one of two operating modes.

– Spool Gun – possibility of welding with type Spool Gun welding holder.

The MasterMIG 200 PFC also has a number of features that support TIG welding processes (2T/4T mode, current falling speed adjustment, post-gas) and MMA (Hot Start for easier electrode ignition, Arc Force for easier welding in forced positions, VRD lower no-load voltage).

Compact size, special design and high protection of the device housing provide increased resistance to humidity, salinity and corrosion, making it ideal for shipbuilding – minor repairs and site overhaul. Thanks to its excellent parameters, it can also be used for light manufacturing and service work in other industries.