EASY TO USE AND VERSATILE. IDEAL FOR WELDING STEEL, STAINLESS STEEL AND ALUMINUM

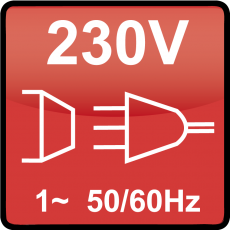

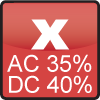

SPARTUS® Easy TIG 210P AC/DC. It is a modern digitally controlled inverter welding machine, constructed on the basis of IGBTs. Allows welding TIG AC/DC and MMA AC/DC modes. It is powered with single-phase 230V source power.

Versatile unit for a wide range of applications. It has a simple-to-use digital control panel that provides instant access to the welding machine’s functions. Allows to weld steel, stainless steel (TID DC pulse welding – allows to weld thin elements). TIG AC welding function allows to weld aluminum and its alloys. Welder is ready to work with TIG torches equipped with remote control (in the handle).

SPARTUS® Easy TIG 210P AC/DC impresses small dimensions and lightweight of just 8,7kg. It is ideal for maintenance, assembly, as well as production works.

Examples of use: portable repair, workshop, maintenance, constructions.

CONTROL OPTIONS:

Standard foot pedal

Potenciometer in the torch