MODERN, DEPENDABLE, DESIGNED FOR WELDING STAINLESS STEELS.

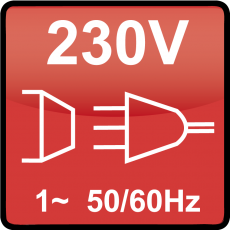

SPARTUS® Master TIG 200P. Small, modern inverter welding machine. Allows gas tungsten arc welding (TIG, GTAW) and manual metal arc welding (SMAW, MMA). Maximum welding current is 200A with high duty cycle 60%. Device is powered from single phase 230V source power.

SPARTUS® Master TIG 200P is equipped with intuitive digital control panel with saving parameters function (10 channels available in memory). The device is capable to precise control of all key parameters in TIG welding, which are presented at simple and easy way on chart the course of the welding process.

TIG pulse welding mode is essential for welding stainless steel components in particular when combining the thin elements. Welder has complete control over the volume of heat input into the material with the ability to adjust the parameters of pulsed current (peak amps, base amps, pulse frequency, pulse width).

Examples of use: light industrial, portable repair, workshop, maintenance, constructions.